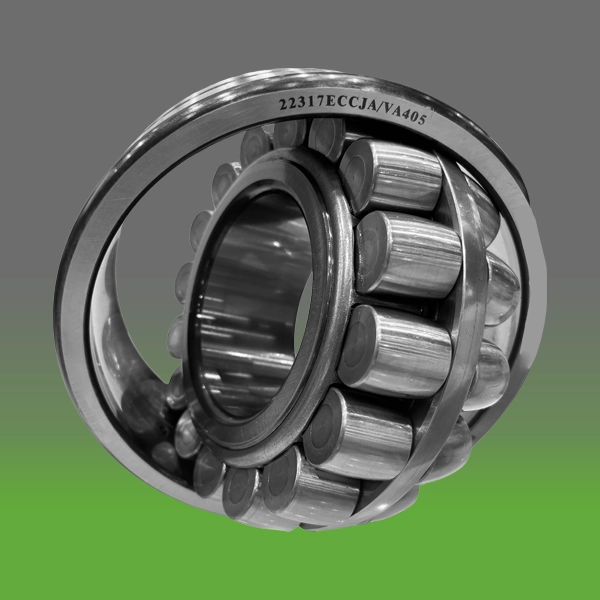

We are bearing manufacturer certified by IATF16949 and ISO9001

A Reliable OEM Supplier Chosen by Many World Reputable Brands

Our Main Products

Quality Control

Our center fitted with full sets of measuring instruments and tools,such as roundness tester,length tester,roughness tester,projector,roller angel and dimension tester.All of standard piece is from ZYS who is famous bearing institution for bearing standard found,research and development in China .

Three procedures for dimension control:

1.Dimension check during process:

- Bore dimension — Self check by workers + Random check by Quality Personnel

- Raceway dimension — 100% Check by Quality person

2.Dimension check before assmebly and before packing:

- 100% Check the dimension before assembly.

- 100% Check the height of finished bearing before packing.

3.Check before delivery:

Random check of the products at a certain rate before delivery.

Our metallographic labs can help us to check the hardness and the metallographic struction of the materil and bearings.

Sample records are taken for each incoming material such as hardness and metallographic.

All incoming parts such as forged ring,rollers and finished bearing are inspected.Our labs and Measuring Center guarantee material quality and dimension accurancy.In addition,our experienced technologists regularly check the dimension and rotation parameter on the site.